Virtual Factory Tour

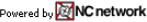

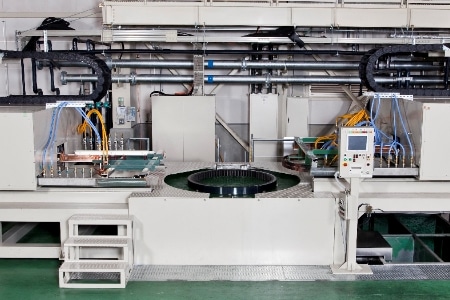

Linear guide rail Hardening Machine

Camshaft Hardening Machine

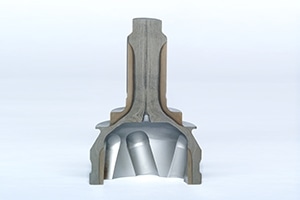

Large Crankshaft Hardening Machine

Driveshaft Hardening Machine

Tempering Furnace

Large Bed Hardening Machine

Biaxial Alternating Vertical Scan Hardening Machine

Vertical Scan Hardening Machine

Large Dip-Spray Hardening Machine

Small Dip-Spray Hardening Machine

Linear guide rail Hardening Machine

Camshaft Hardening Machine

Large Crankshaft Hardening Machine

Driveshaft Hardening Machine

Tempering Furnace

Large Bed Hardening Machine

Biaxial Alternating Vertical Scan Hardening Machine

Vertical Scan Hardening Machine

Large Dip-Spray Hardening Machine

Small Dip-Spray Hardening Machine

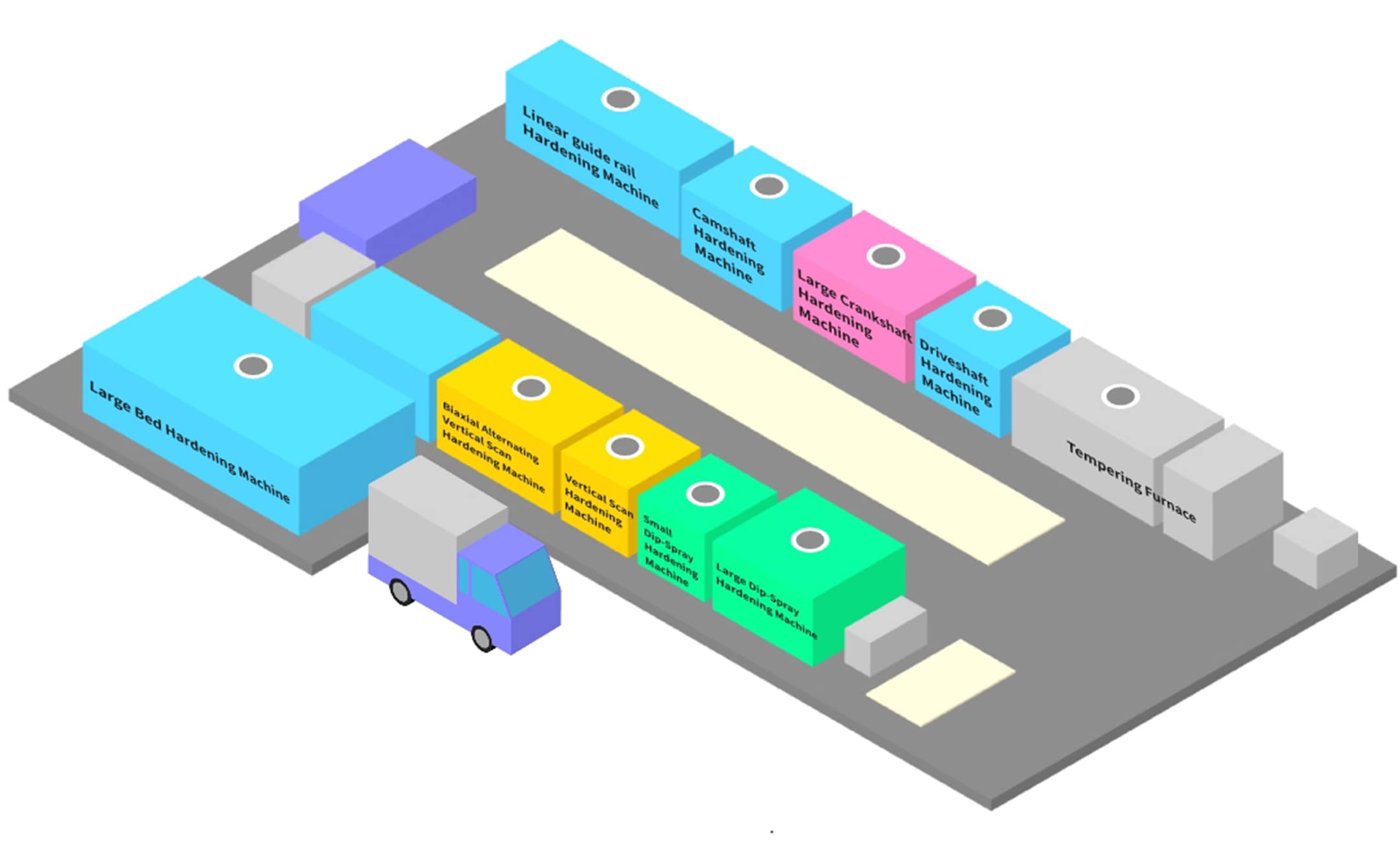

Fully Automatic Index Hardening Machine

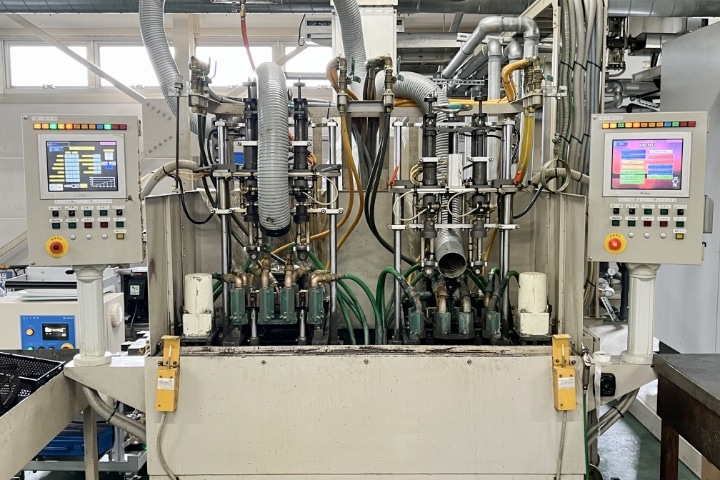

Ball Joint・Tripod Joint Hardening Machine

Biaxial Alternating Hardening Machine

One-Shot Hardening Machine

Indexing Hardening Machine

Fully Automatic Index Hardening Machine

Ball Joint・Tripod Joint Hardening Machine

Biaxial Alternating Hardening Machine

One-Shot Hardening Machine

Indexing Hardening Machine

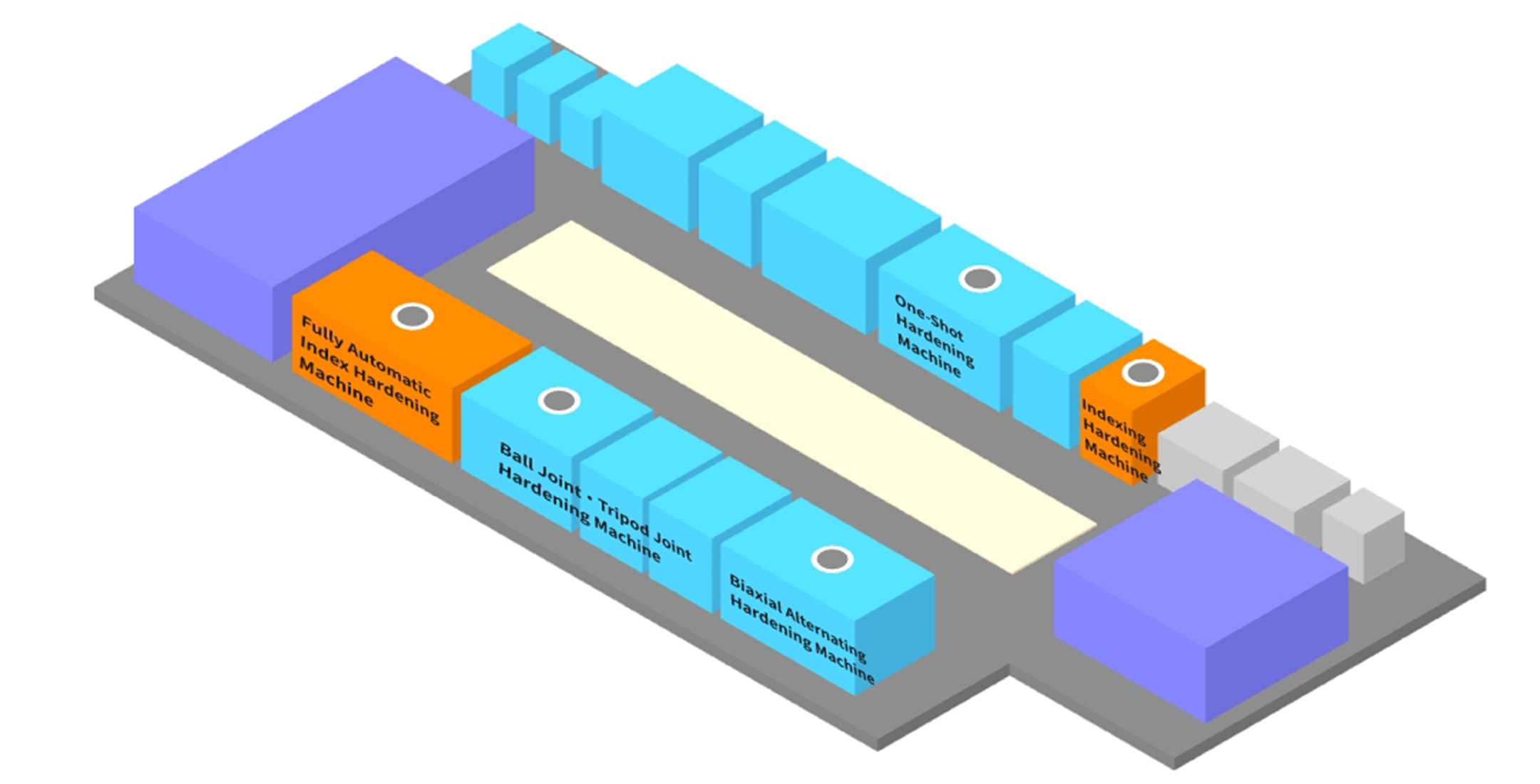

Fully Automatic Yoke Hardening Machine

All-Purpose/Prototype Model Crankshaft Hardening Machine

Ball screw Hardening Machine

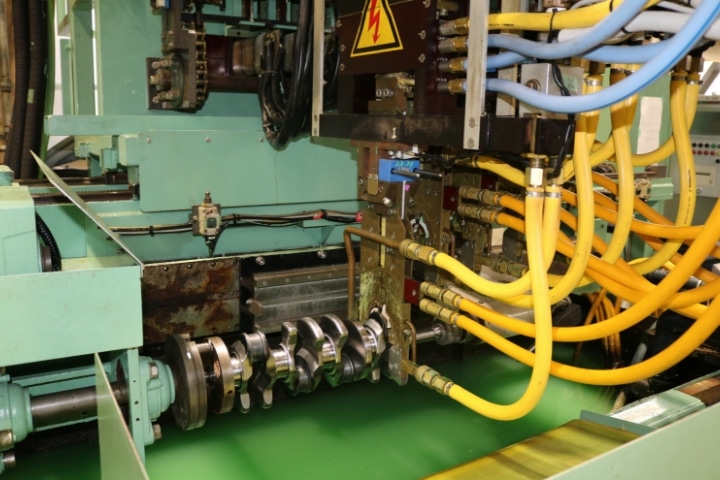

High Production Model Crankshaft Hardening Machine

Horizontal Scan Hardening Machine

Fully Automatic Yoke Hardening Machine

All-Purpose/Prototype Model Crankshaft Hardening Machine

Ball screw Hardening Machine

High Production Model Crankshaft Hardening Machine

Horizontal Scan Hardening Machine

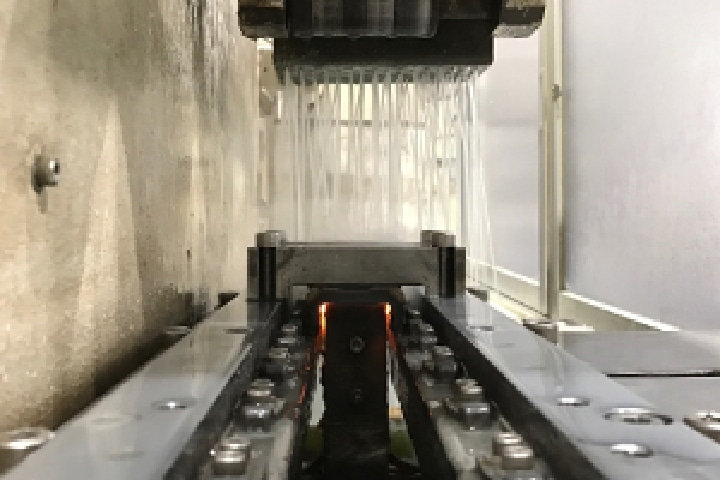

Linear guide rail Hardening Machine

- Rated Output 670kW

- Frequency 10~80kHz

Our specialized original system is the only one in the domestic industry to achieve even hardening and low warpage.

Camshaft Hardening Machine

- Rated Output 450kW

- Frequency 10-30kHz

Adaptable for camshafts of any size by inputting the part dimensions via touch panel.

Suitable for quick prototype testing and development.

Large Crankshaft Hardening Machine

- Rated Output 670kW

- Frequency 10-80kHz

- Max. Length 2.8m

- Max. Weight 250kg

Coil cost minimized by reusing coils on multiple hardening areas, optimal for small lots and prototype trials.

Driveshaft Hardening Machine

- Rated Output 670kW

- Frequency 10-80kHz

Uses our original semi-open rubber coil, adjustable to match the part length, minimizing cost for additional coils and suitable for small lots and prototype testing.

Tempering Furnace

- Max. Length 7m:7m(L)×1.2m(W)×1.2(H)

- Max. Length 3m:3m(L)×1.2m(W)×1.2(H)

For tempering of lots of any size and parts of any shape.

Large Bed Hardening Machine Workpieces Processed: Bed, column, large screws, etc.

- Rated Output 1100kW

- Frequency 10-80kHz

- Max. Length 15m

- Max. Weight 40t

Largest hardening machine for large parts in domestic industry.

Installed with automatic tracking system to maintain gap between part and coil.

Biaxial Alternating Vertical Scan Hardening Machine Workpieces Processed: ball screws, shafts, hydraulic spools, etc.

- Rated Output 670kW / 300kW

- Frequency 10~40kHz / 100~400kHz

Two stations are set up for simultaneous hardening of two shafts, with two converters of different frequencies connected, enabling flexibility for various workpiece shapes from prototype to mass production.

Vertical Scan Hardening Machine Workpieces Processed: Spindle, large/small shafts, etc.

- Rated Output 670kW

- Frequency 10~80kHz

Adaptable for large, small and complex shaped shafts.

Large Dip-Spray Hardening Machine Workpieces Processed: Large/small gears, inner/outer race, cross roller bearing, etc.

- Rated Output 1100kW / 800kW

- Frequency 10-100kHz/10kHz or less

- Max. Diameter Φ1.8m

Small Dip-Spray Hardening Machine (In the case of open spray, it can handle up to φ630)

- Rated Output 670kW

- Frequency 10~80kHz

- Max. Diameter Φ0.45m

This machine heats the full circumference of gears in one shot. The heated gear is then dipped in a quenching water tank and sprayed to achieve an even case depth along the teeth tops and bottoms.

This machine is also used for hardening and reheating of sheave grooves and flat surfaces.

Fully Automatic Index Hardening Machine Processed Workpieces: studs, pin yokes, bushings, etc.

- Rated Output 320-440kW

- Frequency 20-80kHz

Simultaneous hardening of four workpieces of up to φ50 mm diameter and φ150 mm length, and all processes from loading and unloading to after-cooling are performed automatically. This machine is for mass production and is equipped with a robot for transferring the workpieces.

Ball Joint・Tripod Joint Hardening Machine

Shaft Hardening

- Rated Output 500kW

- Frequency 10-70kHz

Performs one-shot hardening with semi-open coil while rotating the part. Achieves even hardening while preventing overheating at the corners of non-linear shafts.

Ball Groove Hardening

- Rated Output 500kW

- Frequency 10-70kHz

Uses a multi-turn coil to harden in a short time without causing warpage.

Excellent coil life of over 200,000 shots.

Tripod Joint Hardening

- Rated Output 500kW

- Frequency 10-70kHz

2-turn coil keeps the coil gap constant, and by initially preheating the part, the amount of heat generated is controlled, achieving even case depth.

Biaxial Alternating Hardening Machine Workpieces Processed: Upper Shaft etc.

- Rated Output 500kW

- Frequency 10-70kHz

Designed to treat parts with multiple hardening areas in parallel hardening stations.

One-Shot Hardening Machine Workpieces Processed: Intermittent Shaft etc.

- Rated Output 150kW

- Frequency 90kHz

Machine consisting of two hardening stations with a single converter for simultaneous hardening of parts with different specifications.

Indexing Hardening Machine

- Rated Output 440kW

- Frequency 100-400kHz

Four small workpieces such as push rods are hardened simultaneously to mass-produce a large number of small items in a short period of time.

Fully Automatic Yoke Hardening Machine

- Rated Output 30kW

- Frequency 10-100kHz

This machine can handle a wide variety of yoke parts. Simultaneous hardening of two parts is alternatingly performed at three stations. Mass production is supported by a robot.

All-Purpose/Prototype Model Crankshaft Hardening Machine

- Rated Output 200kW / 420kW

- Frequency 10-80kHz / 20-50kHz

By changing coils and setting jigs, this model can process all varieties of crankshafts including for automobiles, agriculture machinery, construction machinery, ships, and generators.

Ball screw Hardening Machine

- Rated Output 670kW

- Frequency 10-80kHz

- Max. Length 6m

- Max. Diameter Φ0.2m

Achieves even case depth for screw grooves and controls warpage using support roller.

High Production Model Crankshaft Hardening Machine

- Rated Output 670kW

- Frequency 10-80kHz

Fully automatic model designed to minimize retooling time for different parts and achieve high production quality with short cycle time.

Horizontal Scan Hardening Machine

- Rated Output 670kW

- Frequency 10-80kHz

- Max. Length 2m

Main hardening machine for grooved guide rails using originally designed coil.