Our Track Record (Hardening Equipment)

Our Track Record (Hardening Equipment)

Machine Tools, Industrial Machinery, Robotics

Ball Screws

Semi-Open Coil to Ensure Sufficient Case Depth, Even in Wide Grooves

By passing current through a semi-open coil in the axial direction, sufficient case depth can be ensured, even in wide grooves. Core-less design eliminates the possibility of various issues such as quality degradation due to core deterioration.

Even Cooling Combination Mechanism for High-Precision Lead Pitch and Low Warpage

Achieving uniform cooling after heating leads to high-precision lead pitch and minimal warpage. Our machines are equipped with an Even Cooling Combination Mechanism that intensively cools the groove area and then the entire workpiece for highly accurate and stable hardening.

Original High-Precision Output Mechanism for Compact Equipment

Our original matching unit can move horizontally at high speed, while maintaining stable output to the coil, eliminating the need to move the workpiece and minimizing machine size.

Guide Rails

Original Fixed Coil-Gap Mechanism for Hardening Only Necessary Areas

Even heating of only the necessary areas is achieved through our original mechanism for maintaining a fixed coil-gap between the hardening surface and the coil, resulting in minimal warpage and effect on post-processes.

Continuous Heating and Cooling High-Speed Treatment for Precision Hardening

Long workpieces are heated and then cooled in two stages, while being fed at high speed, to suppress heat conduction inside the workpiece, minimizing warpage and maximizing productivity.

Guide Rails・Blocks

Guide Rails and Blocks of Small Lots of Various Models

The carburizing method commonly used for guide rails and blocks of small lots of various models, has a number of concerns, such as long processing time, quality variation, and post-processing. High-frequency induction hardening can solve these issues by hardening only the necessary areas.

Beds

Coil Auto-Tracker for Even Hardening Pattern

The core requisite to surface scan hardening is maintaining a fixed gap between the coil and workpiece. A high skill level is necessary with large-scale beds and columns as the possibility of deformation under their own weight must be taken into account. Fuji uses displacement sensors to automatically follow the coil to ensure an even hardening pattern.

Coil Auto-Changer for Automatization

When heat-treating a large variety of workpieces in a single day, the time required for operators to manually change coils can be burdensome. To address this problem, we offer a Coil Auto-Changer that greatly reduces the time required for coil changing and prevents coil setting errors.

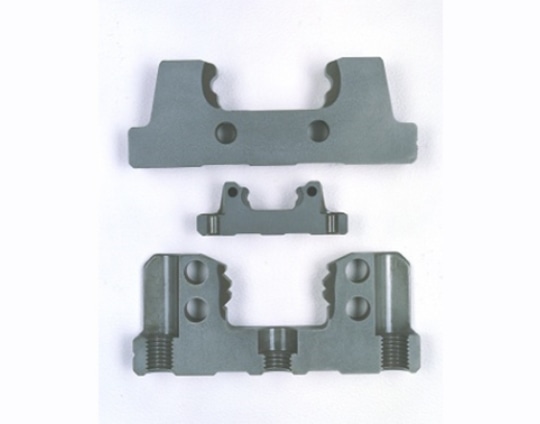

Robotics Parts

One-Shot Quenching of Only Necessary Areas for Low Warpage

By only one-shot hardening only the necessary areas, high quality can be achieved with minimal warpage. Even with workpieces with a shaft, shaft damage caused by unnecessary heat effect does not occur.

High-Productivity

The machine in the photo switches between three hardening machines with a single converter, sequentially hardening workpieces of different sizes. This enables heat treatment processing of various models for high productivity.

Hardening of Roller Bearings Without Cracking or Overheating

Acutely angled grooves of cross roller bearings have difficult geometry that is prone to cracking and overheating if improperly heated and cooled. At Fuji Electronics, we use our original coils and cooling plan to eliminate these problems.

▲